Pioneering work in CAD/CAM automation: Dethleffs relies on WiCAM

News, 21. July 2025

Dethleffs GmbH & Co. KG, based in the Allgäu region of Germany, is one of Europe’s most traditional motorhome manufacturers. For over 90 years, the company has stood for quality, innovation and customer-specific vehicle solutions. In order to consistently implement these high standards in production, Dethleffs relies on state-of-the-art automation – realised by the PN4000 programming system from WiCAM.

Dethleffs GmbH & Co. KG, based in the Allgäu region of Germany, is one of Europe’s most traditional motorhome manufacturers. For over 90 years, the company has stood for quality, innovation and customer-specific vehicle solutions. In order to consistently implement these high standards in production, Dethleffs relies on state-of-the-art automation – realised by the PN4000 programming system from WiCAM.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Technological customisation for maximum variety

Every vehicle at Dethleffs is manufactured individually according to customer requirements. This places the highest demands on CAD/CAM processes. Together with Harald Wilkesmann, founder of the WiCAM Group, a forward-looking automation approach was therefore developed: the software not only controls the machines, but also analyses components independently and automatically determines the optimal machining path.

Dethleffs GmbH & Co. KG

Automated thinking, dynamic programming

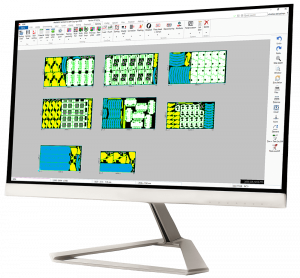

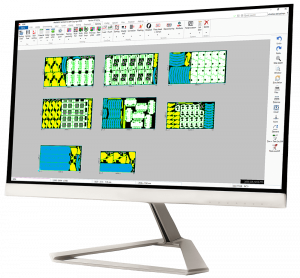

The PN4000 programming system is now at the heart of the entire process automation system. It imports design data directly from ERP and CAD systems, automatically recognises geometries such as drill holes, pockets, chamfers, T-slots or complex 2½-D contours – and immediately generates the appropriate NC programs. In addition, nesting is generated in real time according to requirements.

“We had to automate not only the NC machines but also the programming methods.”

Herbert Heumos, CAM Project Engineer at Dethleffs

Maximum efficiency – with complete flexibility

The system remains responsive even when changes are made at short notice: thanks to functions such as barcode integration, faulty or missing parts can be identified immediately and automatically prioritised for remanufacturing – without any loss of time or manual intervention. PN4000 thus ensures consistently high capacity utilisation, maximum process reliability and sustainable material efficiency.

Early implementation as a milestone for the industry

The PN4000 system was introduced at Dethleffs back in 2004 – at a time when automated CAD/CAM programming in this form was still an absolute exception. For Harald Wilkesmann, founder of the WiCAM Group, the implementation at Dethleffs was a real labour of love and a milestone in the development of intelligent manufacturing software. The close partnership and visionary commitment have led to Dethleffs being featured in the official WiCAM documentation on the company’s history – as an example of true pioneering work in automation.

With PN4000, WiCAM has set new standards at Dethleffs – not only technically, but also strategically: away from rigid program sequences and towards intelligent, dynamic software logic.

Would you like to experience the programming system live?

Get to know the PN4000 programming system in a personal online demo. Whether punching, laser cutting, milling, combination machines or bending – WiCAM offers a powerful CAD/CAM solution for all machining processes.

Get to know the PN4000 programming system in a personal online demo. Whether punching, laser cutting, milling, combination machines or bending – WiCAM offers a powerful CAD/CAM solution for all machining processes.

Machines from almost all leading manufacturers are supported, including TRUMPF, Amada, Bystronic, LVD, HGTECH, Bodorlaser, PrimaPower and many more. We will show you live how you can automate your production, streamline processes and permanently increase your efficiency.

ARRANGE AN ONLINE DEMO

Dethleffs GmbH & Co. KG, based in the Allgäu region of Germany, is one of Europe’s most traditional motorhome manufacturers. For over 90 years, the company has stood for quality, innovation and customer-specific vehicle solutions. In order to consistently implement these high standards in production, Dethleffs relies on state-of-the-art automation – realised by the PN4000 programming system from WiCAM.

Dethleffs GmbH & Co. KG, based in the Allgäu region of Germany, is one of Europe’s most traditional motorhome manufacturers. For over 90 years, the company has stood for quality, innovation and customer-specific vehicle solutions. In order to consistently implement these high standards in production, Dethleffs relies on state-of-the-art automation – realised by the PN4000 programming system from WiCAM.