Schinko programs punching, laser and bending machines with PN4000 • Trumpf TruBend

News, 20. January 2026

What happens when an Austrian precision specialist meets a world-leading automation software provider? Quite simply, production takes a leap into the future:

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Schinko GmbH from Matzelsdorf near Linz – synonymous with high-quality housings, machine and equipment cladding since 1990 – has been demonstrating how to achieve consistent growth in the sheet metal industry for over three decades with around 150 employees: with courage, technological curiosity and uncompromising quality.

Schinko combines state-of-the-art technology, a spirit of automation and genuine passion to create a holistic production concept. From the initial sketch to prototype construction, assembly and maintenance – the customer receives everything from a single source. Schinko’s particular strength lies in demanding special solutions.

The automation turbo since 2020: WiCAM revolutionises the process

When the decision was made in 2020 to digitise the manufacturing processes with WiCAM, a new chapter began:

From the CAD model directly to the machine.

WiCAM’s speciality? Customised solutions that are precisely tailored to everyday production.

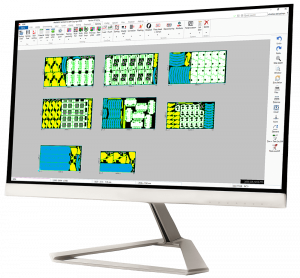

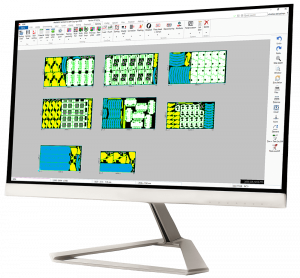

WiCAM’s proven PN4000 programming system was introduced at Schinko to manufacture complex sheet metal assemblies faster and more efficiently. And with great success.

‘What worked very well at WiCAM was their willingness to provide customised solutions.’

Gerhard Lengauer, Managing Director of Schinko GmbH

From laser punching machines to press brakes with a programming system

Responding to special solutions is a key part of what WiCAM is all about. Schinko used to program its Trumpf laser punching combination machines and laser machines as well as its BSK stud welding systems with PN4000 from WiCAM. Recently, the PNBend software module from WiCAM has also been used to control Trumpf bending machines. The programming system works independently of the manufacturer and is the ideal solution for companies with a mixed machine park.

Machines controlled in 2D:

- Trumpf Trumatic 7000 K02 & K08 + SheetMaster

- Trumpf TruLaser 3030 L49 Fiber

- BSK stud welding system

Machines controlled in 3D:

- Trumpf TruBend 5130 B03 TASK 6000

- Trumpf TruBend 7036 B19 TASK 6000

- Trumpf TruBend 5130 B23 Touchpoint

The digital workflow runs smoothly:

Components are designed in SolidEdge, transferred to PN4000 via the Teamcenter interface and checked using a feasibility analysis to determine whether the components can be bent or not.

The highlight: Automatic bolt and pull-through detection

The collaboration between Schinko and WiCAM has resulted in a decisive milestone: PNBend automatically detects bolts and pull-throughs and takes them into account during collision detection in the bending simulation.

- Reduction in susceptibility to errors

- More efficient manufacturing processes

- Savings of entire man-years in production planning

Discover now: The next generation of PN4000 automation

Want to see how you can take your own production to the next level? Then book your personal online demo now! Experience the latest PN4000 version – including optional modules such as:

- 3D editing

- Power nesting

- Advanced bending with PNBend

Whether it’s an update, expansion or new entry: We accompany you from the initial idea to successful implementation.

Arrange an online demonstration